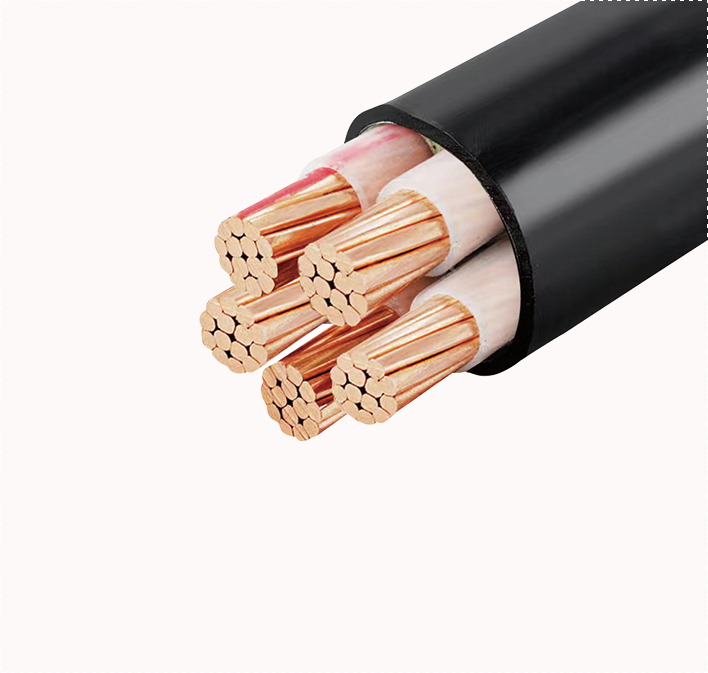

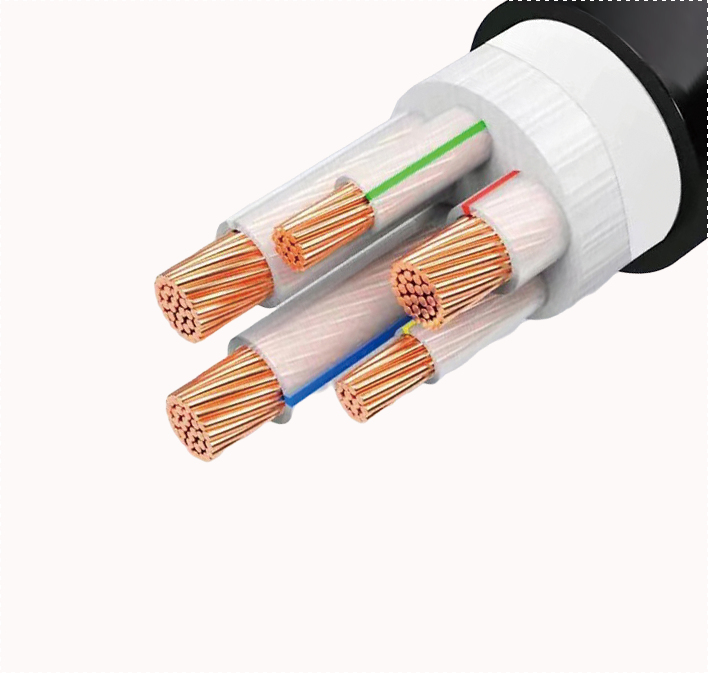

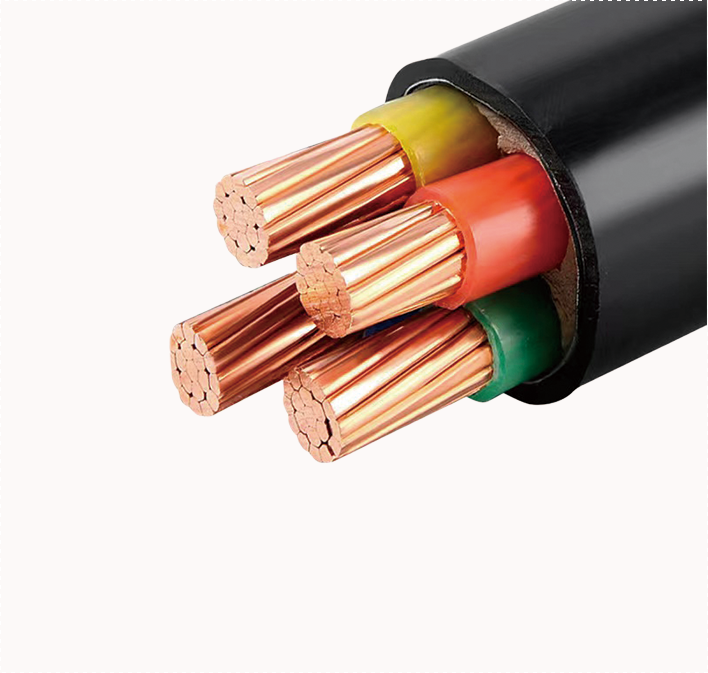

PRODUCT RECOMMENDATIONS

Strictly control the testing standards of each product in the industry to ensure that the output is good.

ABOUT US

A wire and cable manufacturing enterprise integrating R & D, production, import and export trade

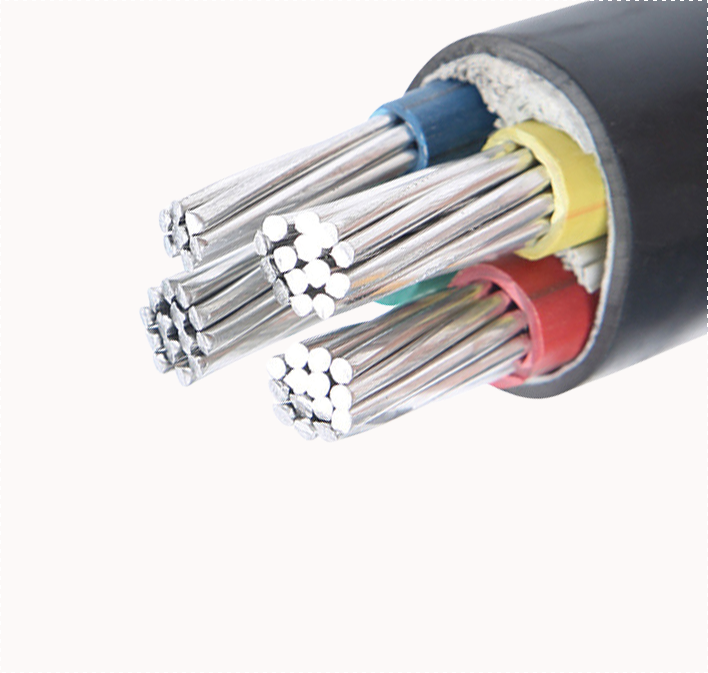

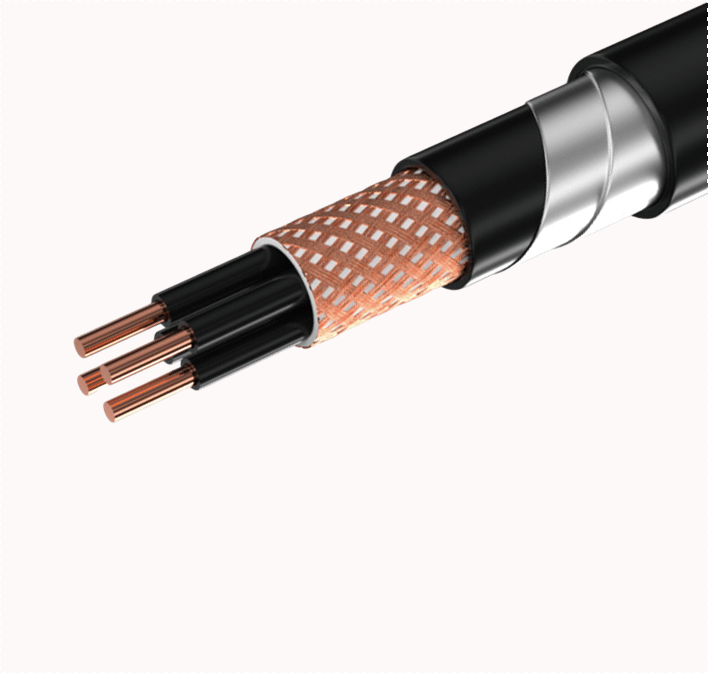

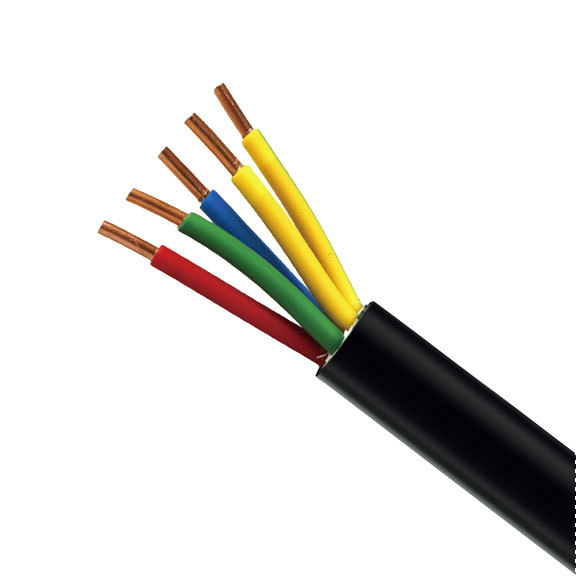

Guangdong Dengfeng Wire and Cable Co., Ltd. was founded in 1988. It is a wire and cable manufacturing enterprise integrating R & D, production, import and export trade. It has a factory building of more than 25000 square meters and a professional technical team. It is equipped with modern advanced production equipment and fully functional testing instruments. The company is headquartered in Jieyang Chaoshan International Airport and Chaoshan high-speed railway station in Guangdong Province. It has unique transportation conditions. Since its establishment, the company has always adhered to the business philosophy of "quality first, pursuit of excellence", established reputation with product quality, and sought development with technological innovation. The products cover more than 30 varieties and more than 1000 specifications such as power cables, control cables, photovoltaic cables, and special wires and cables.

For more than 30 years, the company has paid attention to corporate culture, enthusiastic about social welfare, and comprehensively promoted the construction of the "Dengfeng" brand. Through the implementation of high-end industrial and international strategies, it has continuously optimized the industrial structure and improved product quality and efficiency. It has successively passed the ISO9001 Quality Management System Certification, ISO14001 Environmental Management System Certification, and ISO45001 Occupational Health and Safety Management System Certification. Products through the national CCC compulsory certification, CB certification, the EU EN certification and Germany Rhine TUV certification.

"Dengfeng" enterprises attach importance to management and strictly control quality, and have successively won many honorary titles, such as high-tech enterprises, contract-abiding and trustworthy enterprises, famous brand products of Guangdong Province, famous trademarks of Guangdong Province, and so on. It has been recognized by State Grid, China Southern Power Grid, China Railway Group and the trust of many well-known enterprises and customers, and its development prospects are extremely broad.

Company establishment

Specifications and models of products

Existing plant

High-quality cooperative customers

ENGINEERING CASES

Our advantage

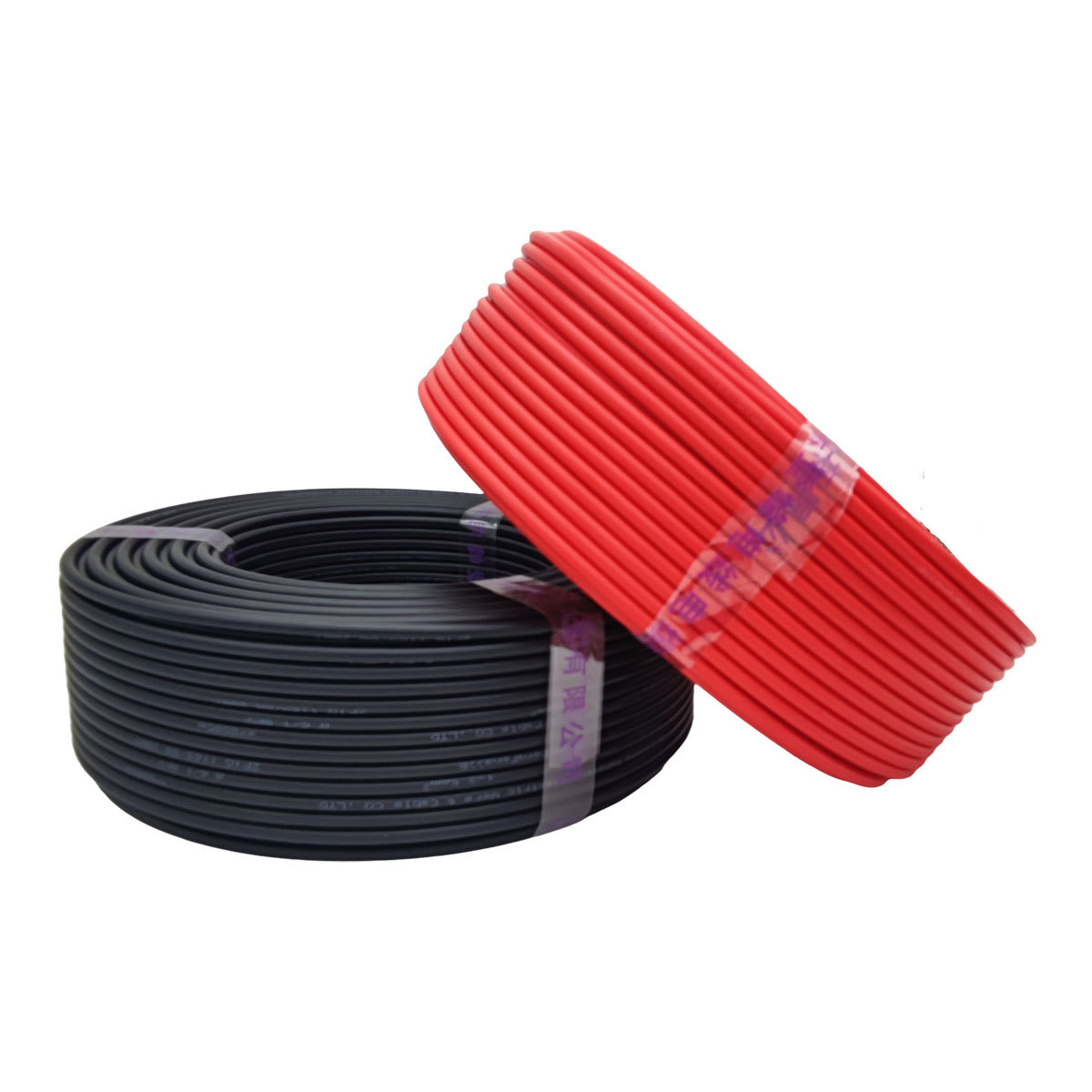

To establish a reputation with product quality and seek development with technological innovation. The products cover more than 30 varieties and more than 1000 specifications such as power cables, control cables, photovoltaic cables, and special wires and cables.

Rich production experience

We have more than 35 years of production experience, to bring you better products and services, so that you can rest assured.

Complete qualification and honor

Products through the national CCC compulsory certification, CB certification, the EU EN certification and Germany Rhine TUV certification and so on.

R & D Design Team

The existing technical team has long-term research and production research and development capabilities, rich management experience, and innovative spirit.

Manufacturing Equipment

Production and manufacturing equipment, to ensure product quality and stable performance, has been working with the majority of customers, with brilliant!

OUR HONOR

NEWS CENTER

Pay attention to the dynamic of climbing the peak

Timely understand the news of Dengfeng wire and cable and the fresh information of the industry

2023/11/17

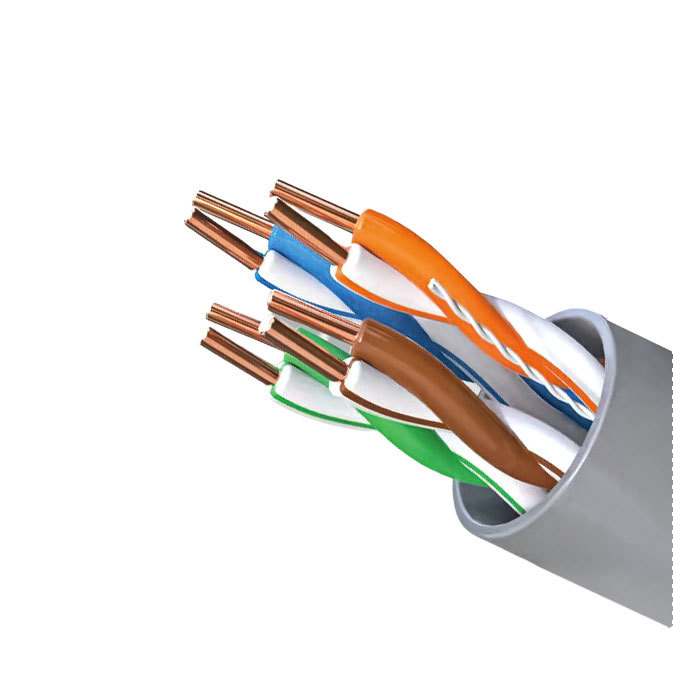

Why can't strong and weak electricity go together

Strong and weak wires are generally not recommended to be placed together because their voltage and current parameters are different. If placed together, it is easy to cause interference and mutual influence, which can affect the normal operation of electrical equipment. Strong wires generally refer to wires with a voltage greater than 220V, such as power lines, light lines, etc. in households. Weak wires generally refer to signal lines with lower voltage, such as telephone lines, network lines, monitoring lines, etc. The voltage and current parameters of strong and weak wires are different. If they are placed together, it is easy to generate electromagnetic interference and crosstalk, which can affect the transmission and reception of weak electrical signals and even damage electrical equipment. Therefore, in order to ensure the normal operation of electrical equipment, strong and weak wires should be laid separately, or isolation measures should be taken for protection. For example, in buildings, strong and weak wires should be laid separately in different pipelines or cable trays, or protected by isolation measures such as metal shielding.

2023/08/28

What are the models of high-temperature resistant wires and cables? In what scenario is it used?

When renovating some factories, we often hear renovation technicians say they need to use high-temperature resistant cables. So what are high-temperature resistant wires and cables? What are the differences from regular cables? What are the models of high-temperature resistant cables? Let's learn about it together with the Buying and Selling Treasure editor. High temperature resistant wires are used as connecting wires for electrical instruments and transmission lines for automatic control systems with rated AC voltages of 450/750V and below. Compared with ordinary cables, high temperature resistant wires have the characteristics of corrosion resistance, strong alkali resistance, strong oxidation resistance, waterproof, wear-resistant, acid alkali resistance, aging resistance, non combustible, electrical insulation performance, high voltage resistance, moisture resistance, etc. They have a long service life, are safe and reliable, and are widely used in aerospace, locomotives and vehicles Energy, steel, non-ferrous metal smelting, oil extraction, electric motors and other fields. High temperature resistant cables with long-term continuous working temperatures of 125 ° C, 135 ° C, 150 ° C, 180 ° C, 200 ° C, 250 ° C, and above are commonly used, including irradiated polyethylene stems, silicone rubber, fluororesin, polyimide, mica, magnesium oxide, and other cables. High temperature resistant cable models include YGC, KGG, KFV, KFF, etc. Specifically, as follows: KFF: Fluoroplastic insulated and sheathed control wires and cables KFFP: Fluoroplastic insulated and sheathed shielded control wires and cables KFFR: Fluoroplastic insulated and sheathed control flexible wire and cable KFV: Fluoroplastic insulated polyvinyl chloride sheathed control wire and cable KFVP: Fluorine plastic insulated polyvinyl chloride sheathed shielded control wire and cable KFVR: Fluorine plastic insulated polyvinyl chloride sheathed control flexible wire and cable KFVRP: Fluorine plastic insulated polyvinyl chloride sheathed shielded control flexible cable KFV22: Fluorine plastic insulated polyvinyl chloride sheathed steel strip armored control wire and cable KFVP22: Fluorine plastic insulated polyvinyl chloride sheathed steel strip armored control wire and cable KFVR22: Fluorine plastic insulated polyvinyl chloride sheathed steel strip armored control flexible wire and cable Wire and cable KFVRP22: Fluoroplastic insulated PVC sheathed steel strip armored shielded control flexible wire and cable KFFV22: Fluoroplastic insulated and inner protective package PVC outer sheathed steel strip armored control cable wire KFVRV22: Fluoroplastic insulated and inner protective package PVC outer sheathed steel strip armored control flexible cable wire High temperature resistant cable product execution standard: Q/HHTZH004.1; The flame retardant and fire resistance characteristics test shall comply with the GB12666-90 standard. AC rated voltage: U0/U, 450/750KV* High working temperature: For example, the insulation of perfluoroethylene propylene (F46) should not exceed 200 ℃. The above is what high-temperature resistant wires are and common models, hoping to help you

2023/11/17

Why do most wires and cables use copper as the core?

Why do most wires and cables use copper as the core? Because copper ranks second among all non-ferrous metals in terms of conductivity, the copper content in cables cannot be lower than 99.5%. Why not use silver with the highest conductivity to make wire cores? Mainly due to the high cost, low toughness, and easy breakage of silver. In addition to copper, aluminum is also a commonly used cable material. Aluminum has low cost and light weight, but has drawbacks such as oxidation. Therefore, long-distance overhead transmission of aluminum wire is more suitable. For copper wire, it carries a larger current. Therefore, when engineering scenarios require it, it is best to choose copper wire as the conductor.